GEMCO Sawdust Briquette Machine for Sale

GEMCO sawdust briquette machine applies advanced solid biofuel forming technology. It can press the loose raw material like agricultural waste, forestry waste, etc. into small volume and high density bio fuel through the process of crushing, drying, briquetting, cooling, etc. After briquetting, the biomass briquettes are easy to store and transport. Their heat value is increased more than a dozen of times.The sawdust briquette machine adopts screw prepressing preheating, piston stamping and two-stage pressing technology, which solves the shortcomings of requiring more about moisture content, and fast wearing of forming mold.

GEMCO sawdust briquette machine consumes less energy, has high production efficiency, long working life and low maintenance rate.

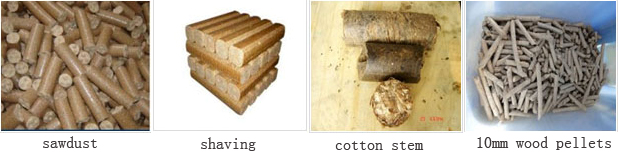

Sawdust briquette machine raw material

- Crop stalk, straw, rice husk, peanut shell, cotton stalk, sawdust, wood chip, shaving, tree bark, bamboo powder, furfural residue, etc.

- The raw material moisture content shall keep at around 15% (wet raw material shall be dried before production), length be kept less than 10mm (large size raw material need to be processed by crusher).

sawdust briquette machine features

- Wide raw material range.

- Small in size, compact in structure, easy for operation, and be moved to anywhere for production.

- Users can choose different shapes for the sawdust briquettes.

- Low investment and running cost.

- Low power, suitable for family and workshop production.

Sawdust briquette machine production process

Raw material dried by sawdust dryer (till moisture content to 15% or so) → feed into the sawdust briquette machine → briquetting under high temperature and high pressure → sawdust briquettes cooling → packing → sawdust briuqettes

The forming principle of sawdust briquette making machine

The eccentric gear of briquette machine drives the pulley to move advance and return 280 times per minute, and the screw feeding machine begins to feed the raw material into briquette machine. Then the raw material is extruded by the punch and forming mode, its temperature rises, it becomes soften and the volume becomes small. Since the forming mold has certain taper, the punched and extruded raw material becomes dense and hard, and then briquettes are formed and ejected from the forming mold.

The forming of sawdust briquettes is affected by temperature and pressure. The sawdust briquette making machine utilizes the momentum principle of crank block. In normal operation, the crank block will punch 280 times every minute, and the pressure can reach 300 tons, temperature reach 150-200℃. So it has better adaptability to different kinds of raw materials, and the forming density is excellent. Every component of the sawdust briquette machine is forced to be filled lubrication oil by the oil pump, so that the equipment is well protected.

sawdust briquette machine quality assurance and after sales service

- Pre-sale service: GEMCO provide product introduction, technical guidance, business plans for customers.

- On-purchase service: GEMCO can offer machine installation guidance, or even on-site installation for customers, trouble-shooting, and maintenance service.

- After sales service: we offer free after sales service for customers. If you need spare parts for the sawdust briquette machine, we can offer you at any time.

Product List

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Project

News

Celebration for 14 Anniversary Day of Our Company’ Founding

Sep 10, 2018

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

ABC Machinery Attend The 122th Autumn Canton Fair

Oct 18, 2017

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

Copyright Notice

May 19, 2017

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...