Lignite Coal Briquette Press Beneficial for the Environment

Coal enterprises customers, after drying coal and coal powder, want to press them into briquette by lignite coal briquette press for the convenience of transport. No matter what the shape is, the purpose is very simple, just for storage and transportation is convenient. Otherwise, like this powder material could be easily cause environmental pollution in the transport process.What is lignite coal?

Lignite coal through the lignite coal briquette press, the degree of coalification between peat and bituminous coal, high water content, easy to weather in the air. Containing a certain amount of native humic acid, low carbon content, high oxygen content, hydrogen content changes. Volatile general in 45% to 55%. As the lignite coal water content is high, low calorific value, easy to weather and spontaneous combustion.

The transportation cost of per unit of energy is high and is not conducive to long-distance transport and storage. The thermal efficiency of lignite coal direct combustion of is low, and greenhouse gas emissions are also great. Difficult to large-scale development and utilization. In addition, lignite coal as raw material conversion is also limited. Only after deep processing, the use of lignite coal is more effective.

What is lignite coal briquette press?

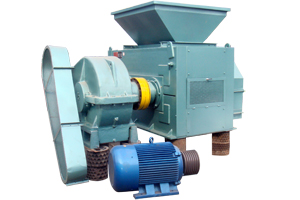

Lignite coal briquette press is a briquette making device which can continuously send all kinds of dry and wet powder to the roll nip through the preloading device, and press the dry and wet powder under the pressure of the roll nip into briquette.

Lignite coal briquette press make lignite coal through a special mold, pressed into a specific shape. Not only improve the burning value of lignite coal, but also facilitate the transport. Therefore, lignite coal briquette press in the application of lignite coal becoming more and more widely.

The advantages of lignite coal briquette press

Our company in the development of scientific and technological research production process. The process adopt precision casting and a molding technique, the material adopts nickel, chromium, manganese, molybdenum, titanium and other alloy materials, with high strength, good toughness, good wear resistance, and other significant features. To solve the roll is not wearable problems, the model is assembled with an alloy wear-resistant square polygonal briquette roll.Lignite coal briquette press can make full use of lignite, reduce the cost of fuel and improve the calorific value of coal. Has a high economic efficiency. In addition, the equipment is small, reduces the area occupied. Does not require carbonization drying equipment, does not require steam, saves investment. At the same time, the effective use of cheap coal for manufacturers, instead of high-priced coal, thereby reducing production costs and improve economic efficiency. Providing a reliable guarantee.

Product List

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Project

News

Celebration for 14 Anniversary Day of Our Company’ Founding

Sep 10, 2018

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

ABC Machinery Attend The 122th Autumn Canton Fair

Oct 18, 2017

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

Copyright Notice

May 19, 2017

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...