what do I need for complete charcoal briquette plant

Complete charcoal briquette plant is used to produce charcoal briquettes from biomass like sawdust, rice husks, coconut shell, sugar cane trash, coffee husks, groundnut shells, coir pith, sugarcane bagasse, corn stalks, silk cotton pods, cotton stalks and jute sticks, etc. The reason why we make charcoal briquettes from these materials is that, they are good source for solid biomass fuel making since they contain lignin, an important factor that makes them able to burn. Otherwise they may be threw away and wasted.

To make charcoal briquettes from waste biomass, you must have a complete business plan, which include all the equipments used in the charcoal briquette making plant.

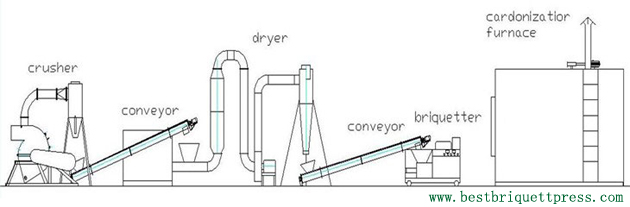

The charcoal briquette making process includes:

Raw material→ crushing→ drying→ raw biomass briquette making→ charring or carbonization→ charcoal briquettes. Different steps need different equipments.

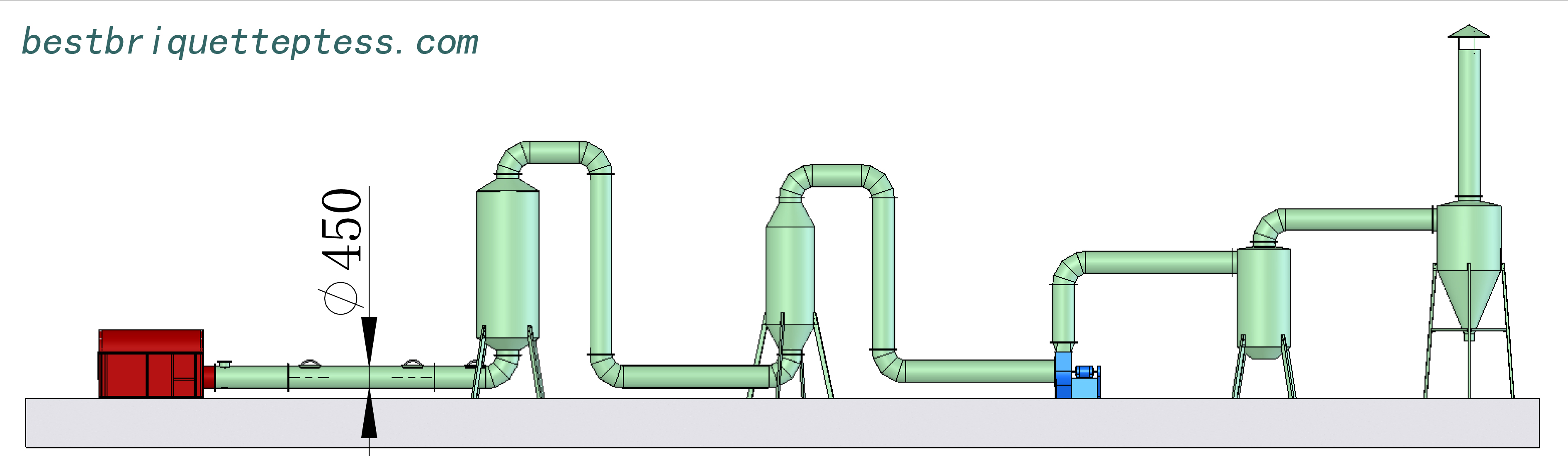

complete charcoal briquette plant flow chart

Composition of complete charcoal briquette plant

1.Crushing SystemUsed to crush the raw biomass material. Sometimes your raw material is sawdust that is 2-5mm in diameter, but most of the time the raw material is wood chip, log or crop waste. Under such circumstance, the crusher/hammer mill is necessary to reduce their size. The wood log even requires a wood chipper to be cut into smaller chips and able to be put into the crusher.

2.Drying System

To guarantee the quality of charcoal briquettes, it is vital to make good quality raw biomass briquettes. The quality of raw biomass briquettes is not only determined by briquette making machine and technology, but also the moisture content of raw material. Generally the standard briquette making moisture is below 10%. Therefore, you need to dry the wet raw materials. If the biomass raw material contains too much water, you can put it in the open-air for 1-2 days to let the surface moisture evaporate, which is a good way to decrease drying time and energy consumption. Then you feed the raw material into the hot air dryer to reduce its moisture content to <10%. The drying temperature is about 140-300℃.

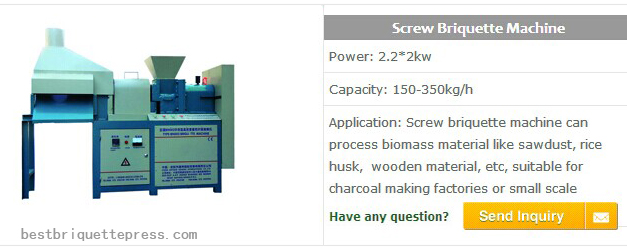

3.Biomass briquette making machine

The biomass briquettes are produced by biomass briquette machine. the most widely used briquette machine for charcoal briquettes making is screw briquette machine because the briquettes made by this model have regular shape and easy to combust. The forming socket of the biomass briquette machine has a heating ring outside its cover, which can increase the temperature inside the forming socket to around 350℃. To make sure the briquettes have smooth surface, high density and no crack, we can choose the suitable forming temperature according to the raw material category and moisture content. The best temperature for briquette making is determined by tests. Generally if the raw material moisture content is 6-10%, the briquetting temperature can be 140-500℃.

4.Charring/carbonization furnace:

The charring of low or medium temperature charcoal can be divided into 3 temperature phases:

- Drying phase: from the ignition to temperature reaches 160℃. In this phase the moisture inside the biomass briquettes is mainly evaporated by external heat and the heat produced by its own combustion. The chemical composition of briquettes remains the same.

- Initial carbonization phase: in this phase, the heat is mainly produced from the combustion of briquettes, and furnace temperature goes up to 160-280℃. At the moment, wood material of the briquettes react thermal decomposition, and their composition becomes to change. The unstable components like hemicelluloses resolve into CO2, CO and small amount of acetic acid.

-

Comprehensive carbonization phase: the temperature of this phase reaches 300-650℃. In this phase, woody materials react thermal decomposition sharply, and large amount of liquid products like acetic acid, methanol and wood tar are produced. Besides, combustible gases like methane and ethylene are also produced and combust inside the furnace. Both the thermal decomposition and gas combustion generate great heat and cause the furnace temperature to rise. The woody materials are destructively distillated into charcoal.

In addition to the above mentioned equipments, there are also other machines that compose a complete charcoal briquette plant, such as conveyor and packing machine. And knowing the composition of a complete charcoal briquette plant will help you to make your charcoal briquette production business plan!

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...