Clean Coal Briquette Brings You High Quality of Life

Energy is closely linked to people’s social life, the clean energy and a good living condition are inseparable. During the industrial development period, people used fossil fuels a lot which causes great damage to the environment. When people began to realize the environmental problem, they started to develop the clean energy. Then the clean coal briquette comes into people’s view.

Clean coal briquettes are made of coal dust, coking coal etc. If the raw materials are used directly, it will bring many disadvantages. The first disadvantage is pollution, then it will produce waste materials, which is a great waste to the resource. While producing those raw materials into clean coal briquettes solves the above problems.

When processing the raw materials, we need use a machine, coal briquette machine. By using it, the loose coal dust will become the clean coal briquettes with compact structure and high density.

Clean coal briquettes are made of coal dust, coking coal etc. If the raw materials are used directly, it will bring many disadvantages. The first disadvantage is pollution, then it will produce waste materials, which is a great waste to the resource. While producing those raw materials into clean coal briquettes solves the above problems.

When processing the raw materials, we need use a machine, coal briquette machine. By using it, the loose coal dust will become the clean coal briquettes with compact structure and high density.

Working Principle of Clean Coal Briquette Machine

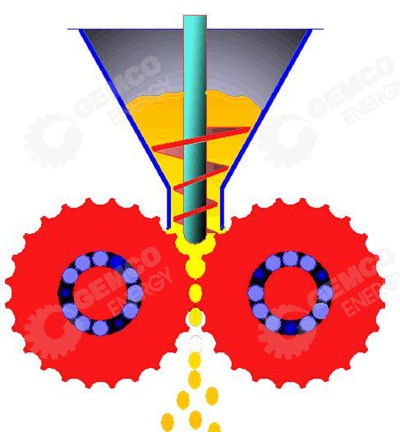

Coal briquette machine adopts the principle of double-roller compression. The materials come into the hopper uniformly from the storage bin by the quantitative equipment. Then the materials go evenly into the middle of both rollers by adjusting the stuff gate. The two rollers rotating at the same speed in the opposite direction will press the materials, and the pressure increases from weak to strong. At the center line of both rollers, the pressure gets to the maximum value. When the materials pass this line, the pressure becomes smaller and smaller until the ball leaves the both rollers. Then the clean coal briquette is finished.

To meet the requirement of shaping materials, prepressing screw adopts electromagnetism adjustable-speed motor, and the users can change the rotating speed properly according to the molding situation to get the highest molding rate and the largest yield.

Requirement to The Materials

- The granularity should be between 80-200 mesh.

- There should not be any metal object, otherwise it will damage the surface of roller.

- The materials supply should be sufficient, so it is suitable to adopt the screw feeding machine that can adjust speed.

| Model | Capacity | Power (kw) | Speed of main shaft | Type of pressure | Material of roller | Form of structure |

|---|---|---|---|---|---|---|

| GCXM-10 | 10TPH | 18.5-30 | 13r/min | Mechanical &Hydraulic | 65Mn/9cr2Mn | Four roller double press |

| GCXM-15 | 15TPH | 30-45 | 13r/min | Mechanical &Hydraulic | 65Mn/9cr2Mn | Four roller double press |

| GCXM-20 | 20TPH | 55-75 | 13r/min | Mechanical &Hydraulic | 65Mn/9cr2Mn | Four roller double press |

| GCXM-30 | 30TPH | 75-90 | 10r/min | Mechanical &Hydraulic | 65Mn/9cr2Mn | Four roller double press |

The above machines are several types of the clean coal briquette machine, and there are other types of machines that have not been shown. We have several types of coal briquette machine for clients to choose, and the clients can choose their favorable type according to the needs.

Product List

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Project

News

Celebration for 14 Anniversary Day of Our Company’ Founding

Sep 10, 2018

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

ABC Machinery Attend The 122th Autumn Canton Fair

Oct 18, 2017

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

Copyright Notice

May 19, 2017

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...