How to Build Your Coal Briquetting Plant

The coal briquette manufacturing plant can make briquettes fuel to supply thermal power plants, chemistry, metallurgy, refractory material factories, and heating. Coal has been the most widely used fuel in many countries for hundreds of years. Traditionally people use raw coal to burn, but raw coal is neither fully combusted, nor easy for storage or transportation. As a result, coal briquetting machine is invented to make coal fines into regular briquettes. The briquetting machine cannot use singly, so customers usually buy complete briquetting plant for coal.What are the purposes of coal briquetting plant?

The round, oval or pillow shape coal briquettes can sell at higher price than raw coal.Besides making coal briquettes, this kind of plant can also process charcoal, coke powder, etc.

The coal briquette plant is stable, highly efficient, easy to maintain, need low investment but has quick return. You do not need much labor for running the plant, so that labor cost is saved.

coal briquetting plant for industry

The briquetting plant for coal mainly compose raw coal storage bin, vibrating sieve, coal crusher, mixer, coal briquetting machine, dryer, etc.

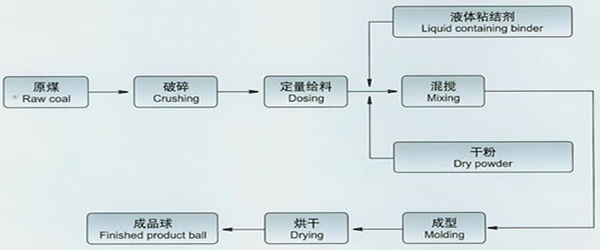

coal briquetting plant for home

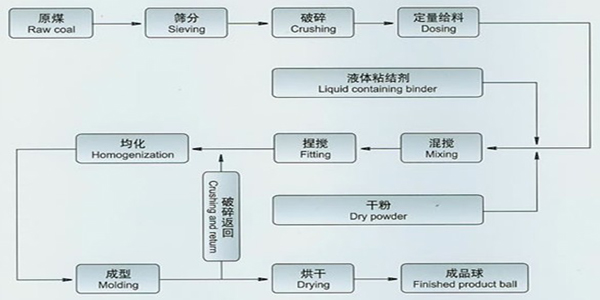

Coal briquette plant production process

- The storage bin is used to store the raw coal, and a vibrating sieve can screen the coal, so that only those coal pieces under required feeding size (200/300mm in diameter) can go into the crusher.

- The crusher is used to crush the coal of 200/300mm size into less than 3mm coal powder. The coal crusher is efficient equipment.

- After crushing, the coal powder shall be mixed with binders. The doser can match coal powder and binder in certain proportion. When both the coal powder and binder are fed into the mixer, water (if necessary) is also fed into the mixed raw material in order to adjust the moisture of raw material.

- Then the mixed coal powder is fed into the coal briquetting machine according to its capacity. The coal briquette shape can be round, oval, pillow, or any other shapes.

- After briquetting, coal briquettes need to be dried by vertical dryer. The heat source of dryer can be coal, gas or oil. After drying, the coal briquettes can be packed or stored.

What are the principles on choosing binder for coal briquetting plant?

The selection of binder shall depend on the following factors:- The stability of coal species and coal ingredients

- The ingredients of binder and final product quality standard (such as content, moisture, fineness, etc.)

- The proportion, fluidity and penetrability of binder

- The relationship of binder proportion, adding method and raw coal moisture content.

- The reasonable and effective use of bentonite.

Product List

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Project

News

Celebration for 14 Anniversary Day of Our Company’ Founding

Sep 10, 2018

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

ABC Machinery Attend The 122th Autumn Canton Fair

Oct 18, 2017

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

Copyright Notice

May 19, 2017

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...