Anthracite Coal Briquetting Machine Making Coal Briquettes

Anthracite coal is an energy resource, but its powder is often abandoned. In fact, it can be processed by anthracite coal briquetting machines to have economical benefit.

What is anthracite coal?

Anthracite coal is an important kind of energy and chemical resource in many countries. With the increase of total coal and the development of mining technology, the yield and proportion of anthracite coal is also increasing year by year.

The anthracite lump coal is hot sale because of gas making and large amount of civil use, but the anthracite coal dust is overstocked because of its narrow usage and little consumption. This is not only a waste of resource, but also pollution to environment.

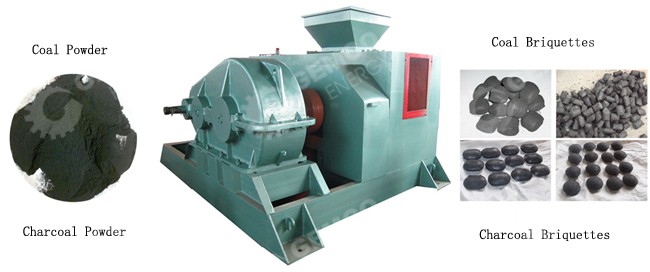

GEMCO anthracite coal briquetting machine.

Over years of research and development, GEMCO has developed anthracite coal briquetting machines to make full use of the anthracite coal dust, and has developed several plants domestically.

Practice has proved that use anthracite coal dust as main raw material and add small amount of binder to be processed by anthracite coal briquetting machines, then through destructive distillation can make good quality anthracite coal briquettes.

How the anthracite coal briquetting machines make coal briquettes?

- Prepare the anthracite coal dust. The preprocessing requires the coal dust be crushed to particle size smaller than 3mm, sometimes other kind of coal need to be added in certain proportion. Then add water and binder and fully mix them. The prepared raw material is conveyed by belt conveyor.

- Briquetting. The mixed raw material is conveyed to the anthracite coal briquetting machines. After briquetting, the anthracite coal briquettes must have 50N/briquette initial cold strength. Then the briquettes are sieved, and the coal powder will be recycled for twice briquetting.

- Drying. There are several kinds of drying methods: the pool drying kiln is simple and reliable, but it occupies too much area, and the labor intensity is high, so it is only suitable for small productivity; while the tunnel drying kiln has many forms like larry type, double row type or steel wire mesh belt type. When choosing such drying method, it must depend on the productivity and the conveying way before and after drying. After drying, the moisture content of anthracite coal briquettes will be decreased to 2%, and intensity to 500N/briquette.

- Storage. After drying, the coal briquettes are usually stored in waterproof stock bin to wait for further coking.

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...