How to Make Fuel Briquettes from Biomass

What is biomass energy?

Biomass now has become a main source for making renewable energy. It can be made into methane, biogas, charcoal, liquefied fuel or other solid fuel. While the most popular and widely applied way is to make biomass into fuel briquettes.Biomass briquettes are solid biofuel pressed from sawdust, wood, straw, grass, stalk, peanut shell, sunflower husk, sugar residue, lees, bagasse, coconut shell, coffee grounds, corrugated carton, etc.

How to make biomass fuel briquettes?

The production of biomass fuel briquettes goes this way: (if you have coal or charcoal as raw material, see how to make coal briquettes.)1.Biomass raw material collection

For making fuel briquettes, you must have sufficient quantity of raw material supply. This is the guarantee for continuous production. Usually the fuel briquette plant is advised to build near the raw material, so that transportation cost is saved.

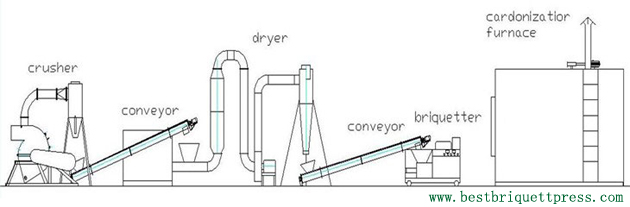

2.Biomass grinding/crushing

Most of the time, your raw material is larger than the required briquetting size: 2-5mm, so it shall be grinded or crushed first (if raw material is 3-5mm sawdust, this step is unnecessary). For crushing the raw material, a crusher is needed. The capacity is in accordance with that of fuel briquette machine. For wood logs, the wood chipper is also needed. After crushing, the raw material can be 2-5mm in size.

biomass fuel briquettes line for charcoal briquettes

Those biomasses like wood, fresh straw or stalk may contain too much moisture that is higher than 8-12% (as required). As a result, they shall be dried before briquetting. The dryer (airflow dryer or drum dry) is indispensable for a complete fuel briquette plant.

4.Briquette making

The most important equipment for making bio fuel briquettes is bio fuel briquette machine. There are mainly 3 types of bio fuel briquette machines made by GEMCO: screw briquette machine, mechanical stamping briquette machine, and hydraulic briquette press. Screw briquette machine is usually used by those who make biomass fuel briquettes or high quality charcoal briquettes for sale. The briquettes made by screw briquette machine have regular shape and good appearance, which give them a good price. The mechanical stamping briquette machine is usually used in large biomass briquetting plant which produces fuel briquettes for industrial use. Hydraulic briquette press has comparatively small capacity, which is good for small plants that require more about the cleanness of production environment.

5.Fuel briquettes cooling and packing

After made by the briquette machine, biomass fuel briquettes are very hot and need to be cooled. They can be cooled by air. Then if the fuel briquettes are for sale or for storage, they shall be packed in bags or boxes.

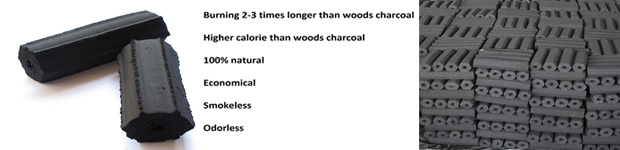

Fuel briquettes made from biomass are widely used in many areas:

- The fuel briquettes can be used for heating, cooking, BBQ, power plants and other industries.

- If made into charcoal, the charcoal fuel briquettes are also used in smelting and chemical industries, agricultural or husbandry fields.

Although you can make fuel briquettes by yourself with some easily get tools, it is still better to purchase a fuel briquette plant if you need regular amount of fuel briquettes supply. Then why not buy one now?

Product List

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Project

News

Celebration for 14 Anniversary Day of Our Company’ Founding

Sep 10, 2018

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

ABC Machinery Attend The 122th Autumn Canton Fair

Oct 18, 2017

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

Copyright Notice

May 19, 2017

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...